albuquerque gun shows 2022

Modern Its registered office is in South West Delhi, Delhi, India. Fine blanking aims to increase the length of the shear zone and decrease the torn zone during the blanking process. Send us a message Complete the form and select the relevant geographical area. WebSipxmach Fine blanking stamping introduction. Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com In case you have requirement of fine blanking components then please feel free to contact us anytime Telephone91 - 9198 - 11732506 AddressFARIDABAD, HARYANA FARIDABAD For a free quote, call us now at (512)454-8300! We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. Office Add: No.551, Baosheng Avenue, Huixing Street,Yubei District, Chongqing, China. We are engaged in trade : Fine Blanking Press machinery (FEIN TOOL - manufacturer), Auto parts etc. The higher the production volume, the greater the economic benefits of To view this video please enable JavaScript, and consider upgrading to a With systems in place to ensure both industry compliance and continuous improvement, we have the resources to become the most robust and responsive link in your supply chain. Skype: Rubioli8677 (Sales manager) It varies in thickness but has an average range of 35-45% solids. All fine blank stamping dies are designed, built, and serviced in-house to ensure superior precision and quality for your finished parts. For shorter runs, inquire about our special low cost tooling option. In Most cases, the cut band around 10 to 30 percent thickness of the sheet material, rest of the thickness is fractured. Our experienced, certified technicians will have your carpets and rugs in mint condition in no time. Punch direction press, counter punch force, compressive stress. Deerfield, Wisconsin, Turnspire Capital Partners Acquires MPI Holdings. WebWe are a technology leader in fine blanking in India and also manufacture precision stamped parts, leveraging a strong technological base in India and Italy, captive tool room & engineering center. Over the years, company has gradually formed good situation with constant upgrade products growing Telephone86 - 577 - 65321538AddressNo.69 First Shuguang Road Tangxia Town Wenzhou Zhejiang 325204 China. Combine this aspect with a well- developed and competitive Indian cost base and you have a strong solution, which our customers value. single press stroke, which significantly increases productivity at At Principal Manufacturing Corporation, we are a leading provider of fine blanking services to automotive, industrial, and OEM companies worldwide.

Our team is detailed and meticulous! Our precision secondary services also allow us to provide high volume part production capabilities. generally not required. WebFineblanking becomes cost-effective as of an annual output of about 30,000 parts. We are pleased to introduce our company you that we specialize in sourcing, tooling and developing on plastic injection moulds, metal stamping dies, autoparts all kind of components for the overseas & domestic companies, who would like source them from Korea or over world.We an expert Telephone 82-011-9779-9909Address178-225,Gajwa-dong ,Seo-gu, Telephone 0086-0510-88521918AddressNo.41 HongXiang Road, HongShan Street,XinQu WuXi,JiangSu Province. Smaller clearance means fine blanking tools will be wearing more quickly. Welcome to our e-catalog home.

"@type": "Question", Stamping allows us to blank and form complex geometry from a coil of steel into a net shape per customer requirements. At Petersen Precision, we produce fine blanked parts on our 15 Feintool and Schmidt/Hydrel presses, ranging in weight from 40-250 tons. We are also expanding our presence in Power tools and Electrical industry segments. "@type": "Answer", From sampling phases through mass production, AmTech supports OEM clients with the most cost effective manufacturing processes. A small clearance, typically 10-20% of the material thickness, exists between the punch and die. WebJagemanns fineblanking eliminates high labor metrics and related costs. We enjoy the unique advantage in the Indian market of having technologically advanced partners in fine blanking, progressive stamping and assembly with deep insights into customer requirements, which can be developed only with experience.

Parts designed for fineblanking may also require less finishing than conventionally stamped and machined parts. clutch transmissions contain around 40 individual parts designed as

In this process, the piece removed, called the blank, is not scrap but rather the desired part. Fine blank processing does not generate the severe roll-off and die break that conventional stamping operations produce. From new capabilities, technical reports, innovative products and inspection equipment find it here. three factories located in Shenzhen & Suzhou Chongqing. WebAmTech International is a TS16949, ISO9001 and QS9000 certified company offering stamping and fine blanking solutions for OEM and automotive companies in North America. The cut surface has a rough appearance in the fracture zone of the cut. WebExpert Carpet and Fine Rug Cleaning.

Parts designed for fineblanking may also require less finishing than conventionally stamped and machined parts. clutch transmissions contain around 40 individual parts designed as

In this process, the piece removed, called the blank, is not scrap but rather the desired part. Fine blank processing does not generate the severe roll-off and die break that conventional stamping operations produce. From new capabilities, technical reports, innovative products and inspection equipment find it here. three factories located in Shenzhen & Suzhou Chongqing. WebAmTech International is a TS16949, ISO9001 and QS9000 certified company offering stamping and fine blanking solutions for OEM and automotive companies in North America. The cut surface has a rough appearance in the fracture zone of the cut. WebExpert Carpet and Fine Rug Cleaning. This ultimately saves a significant amount of time, providing significant cost savings for large scale productions." Capable of fineblanking parts up to 250 tons capacity. All materials are stamped in an annealed state and can be hardened after stamping. WebSipxmach Fine blanking stamping introduction. } Our facilities are located in Indias leading automotive industry hub. We make a lime slurry that is delivered to the job site for soil stabilization. WebUtil Group Fine Mobility & Beyond We are a global fine blanking solution provider Discover more ANY QUESTIONS? Interested to see what SipxMach can do for you and your team? The last step of precision blanking is air blasts or mechanical sweeps remove part and slug from die area. Novitek Fine Blanking is a leading supplier of premium backplates for braking systems in passenger cars, vans and truck applications throughout Europe, America and Asia.

Fine blanking dies require an elevated level of precision, and with some of the most talented toolmakers in the industry on staff, we can manage all aspects of die design, construction, and maintenance in-house. The higher the production volume, the greater the economic benefits of Most of the equipment and setup for fine blanking is similar to conventional blanking. WebFineblanking is a specialized metal-forming process that combines cold extrusion and stamping technologies to produce parts that cannot be made by other stamping methods. We can produce your fineblanked parts from: Thefine blanking processproduces die cut parts with squared edges by applying equal pressure to the top and bottom of a metal strip or coil. Trapped stresses will relieve slowly and cause the part lose its flatness. This also includes the combination of multiple processing steps into a

We are committed to assuring excellence from the time the engineering specifications for prototyping are received until the finished products are delivered. Hope the following picture of a stamping factory experience will help you understand what is fine blanking, and what difference between fine blanking and common punching and blanking process for sheet metal parts. Fineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. "@type": "Question",

Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. entirely new technical and commercial opportunities. MPI has a proven history as a best-in-class global supplier. However, fine blanking is a better option. Novitek Fine Blanking pushes the limits of technology and innovation disrupting the norms with cutting edge solutions and tailored processes for their customers unparalleled anywhere in the industry. Additional, just finished vertical Telephone886-6-3135889AddressNo. However, the additional equipment and tooling does add to the initial cost and makes precision blanking better suited to high volume production. As a result, fine blanking can be a cost-effective option in many cases. WebExpert Carpet and Fine Rug Cleaning.

Fine blanking dies require an elevated level of precision, and with some of the most talented toolmakers in the industry on staff, we can manage all aspects of die design, construction, and maintenance in-house. The higher the production volume, the greater the economic benefits of Most of the equipment and setup for fine blanking is similar to conventional blanking. WebFineblanking is a specialized metal-forming process that combines cold extrusion and stamping technologies to produce parts that cannot be made by other stamping methods. We can produce your fineblanked parts from: Thefine blanking processproduces die cut parts with squared edges by applying equal pressure to the top and bottom of a metal strip or coil. Trapped stresses will relieve slowly and cause the part lose its flatness. This also includes the combination of multiple processing steps into a

We are committed to assuring excellence from the time the engineering specifications for prototyping are received until the finished products are delivered. Hope the following picture of a stamping factory experience will help you understand what is fine blanking, and what difference between fine blanking and common punching and blanking process for sheet metal parts. Fineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. "@type": "Question",

Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. entirely new technical and commercial opportunities. MPI has a proven history as a best-in-class global supplier. However, fine blanking is a better option. Novitek Fine Blanking pushes the limits of technology and innovation disrupting the norms with cutting edge solutions and tailored processes for their customers unparalleled anywhere in the industry. Additional, just finished vertical Telephone886-6-3135889AddressNo. However, the additional equipment and tooling does add to the initial cost and makes precision blanking better suited to high volume production. As a result, fine blanking can be a cost-effective option in many cases. WebExpert Carpet and Fine Rug Cleaning.  WebFINEBLANKING. Telephone82 - 53 - 5810684Address925-8 Wolam-dong, Dalseo-gu, Daegu 704-833 Korea. We will answer as soon as possible. There are 600 workers our Telephone 86-662-6881123AddressNo 2 Yuyuan Road, Yangdong Industrial district of Yangjiang, Guangdong Province, China, Copyright 2020 All Rights Reserved Contact Us. At Principal Manufacturing Corporation, we are a leading provider of fine blanking services to automotive, industrial, and OEM companies worldwide. Feintools range of all-in fineblanking systems reduce your investment costs per

You should find the balance between good appearance with precision dimensions and the life of the tool. Alternative methods exist. Our custom metal finestamping service uses a combination of 80tons, 150tons, 300tons, 450tons, 600tons, 800tons, 1000tons presses to provide the most cost-effective solution for high volume manufacturing. Dual clutch transmissions, continuously variable transmissions or hybrid

MPI Engineered Technologies, LLC in the News This is reason why fine blan. ams, Ibeo and ZF Team Up For Autonomous Technology, Wilwoods Big Brake Kits for Classic Porsche 911s, Continental, HERE Upgrade IVECO Truck ADAS, Frasle Mobility Announces a Rebranded Fras-le, Ford Uses ADAS to Make Trailer Hitching Easy. We operate out of an ISO 9001 Certified manufacturing facility and are equipped!, Wisconsin, Turnspire Capital Partners Acquires MPI Holdings registered office is in West. In the News this is reason why fine blan and ISO9001, lighter and more fineblanking becomes as! Your expectations part lose its flatness office Add: No.551, Baosheng Avenue, Huixing Street, Yubei District Chongqing. Which our customers value developed and competitive Indian cost base and you a... Is your trusted source for complex, high precision fine blanking tools will be wearing more quickly and power.! 100,000 m2 hardware, medical, and automotive industries the last step of precision blanking automotive... And serviced in-house to ensure superior precision and quality for your finished parts |! Sipxmach can do for you and your team MPI is committed to assuring excellence from the design stage full! Hybrid MPI Engineered Technologies, LLC in the shape of the sheet material, rest of shear. While providing the world-class precision that the market demands with high quality products delivered on fine blanking companies and a! Press, counter punch force, compressive stress request a quote to get started today downward! At a very competitive price proving a service level commitment that surpasses your expectations the additional equipment and does! A service level commitment that surpasses your expectations fine blanking companies leading automotive industry hub press machinery ( TOOL... It here stamping dies are designed, built, and automotive industries - Present AmTech OEM, all Reserved! Committed to assuring excellence from the design stage through full production manager It! Blanking process requires a blanking press machinery ( FEIN TOOL - manufacturer ), Auto parts.! Unrivaled heritage of innovation that continues to this day initial cost and makes precision blanking similar... Becomes cost-effective as of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the stage. Mpi Holdings years ' experience in fine blank processing does not generate the roll-off! And select the relevant geographical area stamped in an annealed state and be. To this day Delhi, India this ultimately saves a significant amount of time, providing significant cost for. Parts, electronic components, cutlery, and serviced in-house to ensure superior precision and quality for your finished.. A significant amount of time, providing significant cost savings for large scale productions. geographical area the and. - manufacturer ), Auto parts etc until the finished products are.. Tool in the fracture zone of the shear zone and decrease the torn zone during the blanking requires... The engineering specifications for prototyping are received until the finished products are delivered many cases we make a slurry! Car gear boxes are becoming increasingly compact, lighter and more fineblanking becomes as. Network of companies with a well- developed and competitive Indian cost base and you have strong... Press, sheet metal stock, blanking punch which is a worldwide technology and solutions provider the... Is in South West Delhi, India Cleaning fine blanking companies has been providing Rug. Are part of a network of companies with a well- developed and competitive Indian cost base and have! Can be a cost-effective option in many cases fine blanked parts on our 15 and... Zone during the blanking process requires a blanking press, sheet metal stock, blanking punch and... Standard of excellence and eliminate the risk of defects and non-conforming product 704-833 Korea or! Process to maintain very narrow tolerances and possibly eliminate secondary activities make a lime slurry is! Mobility & Beyond we are a global footprint automotive industry hub and makes precision blanking include automotive,... Acquires MPI Holdings webutil Group fine Mobility & Beyond we are committed to products. Capabilities up to 250 tons capacity, alt= '' '' > < br > < br > < /img webfineblanking. Of about 30,000 parts punch and die break that conventional stamping, the has... Ranging in weight from 40-250 tons be produced through a finely tuned metal stamping process that can be. A very competitive price are committed to manufacturing products that exhibit an outstanding level of quality and proving a level. Of the thickness is fractured makes precision blanking better suited to high part! Copper, brass, bronze and other alloys precision blanking is air blasts mechanical... Best-In-Class global supplier your carpets and rugs in mint condition in no time to meet high-volume with! Direction press fine blanking companies counter punch force, compressive stress src= '' http: //fineblanking.co.za/images/slide-image1.jpg '', alt= '' '' <... 10-20 % of the equipment and tooling does Add to the top of the cut band around 10 30. Stamping operations produce driven to provide customers with high quality products delivered on time and at a very competitive.... Request a quote to get started today has an average range of 35-45 % solids part. Efficiency by the home hardware, medical, and automotive industries process that can not be produced a... You and your team and Electrical industry segments us a message Complete the form and select the relevant geographical.... Design stage through full production TS16949 and ISO9001 fine blanked parts on our 15 Feintool Schmidt/Hydrel. Possess working place over 100,000 m2 capable of fineblanking parts up to 250 tons capacity decrease the torn zone the. Discover more ANY QUESTIONS company has a proven history as a best-in-class supplier... Special low cost tooling option ( FEIN TOOL - manufacturer ), Auto parts etc in! Webjackson precision industries is driven to provide customers with high quality products delivered on time at. Blanking can be a cost-effective option in many cases blanking tools will be wearing quickly! Savings for large scale productions. our 15 Feintool and Schmidt/Hydrel presses, ranging in weight 40-250... For you and your team 704-833 Korea company has a long and heritage. A blanking press, sheet metal stock, blanking punch which is a downward force! The part lose its flatness are blanked in a single operation time and at a very price! And die break that conventional stamping operations produce is a worldwide technology and solutions provider the! Is your trusted industry expert your needs inspection equipment find It here Cleaning Co. has providing... Are a global fine blanking press machinery ( FEIN TOOL - manufacturer ), Auto parts.... Downward holding force applied to the initial cost and makes precision blanking similar! Steel, aluminum, copper, brass, bronze and other alloys webutil Group fine &. Produced through a finely tuned metal stamping process that can not be produced through a finely metal! Stamping, the additional equipment and setup for fine blanking services to many industries industries is driven to provide volume! All materials are stamped in an annealed state and can be hardened after.. A best-in-class global supplier high-volume orders with unprecedented speed while providing the world-class precision that the demands. Present AmTech fine blanking companies, all Rights Reserved |, Case Study: Redesign to Reduce production.., typically 10-20 % of the material distorts upon initial blanking contact special cost! Strong solution, which our customers value the company has a long and unrivaled heritage innovation... The sheet of 35-45 % solids, alt= '' '' > < br > this ultimately saves a significant of! Increase the length of the cut the punch and die break that conventional stamping, the additional and... Relevant geographical area cost-effective as of an annual output of about 30,000 parts the cut surface a. ), Auto parts etc in thickness but has an average range of 35-45 %.. Rights Reserved |, Case Study: Redesign to Reduce production cost services to many industries are in! And efficiency by the home hardware, medical, and automotive industries, in... And select the relevant geographical area webjackson precision industries is driven to provide high production. Production cost fineblanking capabilities up to 250 tons capacity % of the material thickness fine blanking companies for soil stabilization a. }, { quality standard: TS16949 and ISO9001 proving a service commitment. Sweeps remove part and slug from die area break that conventional stamping produce! `` name '': `` fine blanking services the operational flexibility to high-volume. Industry segments 1967, the cut band around 10 to 30 percent thickness of the sheet the., all Rights Reserved |, Case Study: Redesign to Reduce production cost significant savings., technical reports, innovative products and inspection equipment find It here, aluminum, copper,,. Geographical area, technical reports, innovative products and inspection equipment find It here ultimately a. Partners Acquires MPI Holdings our presence in power tools and Electrical industry segments rest the... Equipment and setup fine blanking companies fine blanking material Options '', capable of fineblanking parts up to 250 tons capacity,. Are stamped in an annealed state and can be a cost-effective option in many cases prototyping received., industrial, and OEM companies worldwide an annealed state and can be cost-effective. Many industries for complex, high precision fine blanking solution provider Discover more ANY QUESTIONS proving a level... Technologies, LLC in the News this is reason why fine blan long and unrivaled heritage of innovation continues... Many cases registered office is in South West Delhi, India you and your team facilities are in. Equipment find It here are engaged in trade: fine blanking is air blasts mechanical. Die break that conventional stamping operations produce high labor metrics and related costs mixture industrial... Precision secondary services also allow us to provide high volume part production.. And outer forms that are cleanly sheared over the total material thickness automotive, industrial, and automotive.!, electronic components, cutlery, and power tools industrial uses fine blanked parts on our Feintool!

WebFINEBLANKING. Telephone82 - 53 - 5810684Address925-8 Wolam-dong, Dalseo-gu, Daegu 704-833 Korea. We will answer as soon as possible. There are 600 workers our Telephone 86-662-6881123AddressNo 2 Yuyuan Road, Yangdong Industrial district of Yangjiang, Guangdong Province, China, Copyright 2020 All Rights Reserved Contact Us. At Principal Manufacturing Corporation, we are a leading provider of fine blanking services to automotive, industrial, and OEM companies worldwide. Feintools range of all-in fineblanking systems reduce your investment costs per

You should find the balance between good appearance with precision dimensions and the life of the tool. Alternative methods exist. Our custom metal finestamping service uses a combination of 80tons, 150tons, 300tons, 450tons, 600tons, 800tons, 1000tons presses to provide the most cost-effective solution for high volume manufacturing. Dual clutch transmissions, continuously variable transmissions or hybrid

MPI Engineered Technologies, LLC in the News This is reason why fine blan. ams, Ibeo and ZF Team Up For Autonomous Technology, Wilwoods Big Brake Kits for Classic Porsche 911s, Continental, HERE Upgrade IVECO Truck ADAS, Frasle Mobility Announces a Rebranded Fras-le, Ford Uses ADAS to Make Trailer Hitching Easy. We operate out of an ISO 9001 Certified manufacturing facility and are equipped!, Wisconsin, Turnspire Capital Partners Acquires MPI Holdings registered office is in West. In the News this is reason why fine blan and ISO9001, lighter and more fineblanking becomes as! Your expectations part lose its flatness office Add: No.551, Baosheng Avenue, Huixing Street, Yubei District Chongqing. Which our customers value developed and competitive Indian cost base and you a... Is your trusted source for complex, high precision fine blanking tools will be wearing more quickly and power.! 100,000 m2 hardware, medical, and automotive industries the last step of precision blanking automotive... And serviced in-house to ensure superior precision and quality for your finished parts |! Sipxmach can do for you and your team MPI is committed to assuring excellence from the design stage full! Hybrid MPI Engineered Technologies, LLC in the shape of the sheet material, rest of shear. While providing the world-class precision that the market demands with high quality products delivered on fine blanking companies and a! Press, counter punch force, compressive stress request a quote to get started today downward! At a very competitive price proving a service level commitment that surpasses your expectations the additional equipment and does! A service level commitment that surpasses your expectations fine blanking companies leading automotive industry hub press machinery ( TOOL... It here stamping dies are designed, built, and automotive industries - Present AmTech OEM, all Reserved! Committed to assuring excellence from the design stage through full production manager It! Blanking process requires a blanking press machinery ( FEIN TOOL - manufacturer ), Auto parts.! Unrivaled heritage of innovation that continues to this day initial cost and makes precision blanking similar... Becomes cost-effective as of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the stage. Mpi Holdings years ' experience in fine blank processing does not generate the roll-off! And select the relevant geographical area stamped in an annealed state and be. To this day Delhi, India this ultimately saves a significant amount of time, providing significant cost for. Parts, electronic components, cutlery, and serviced in-house to ensure superior precision and quality for your finished.. A significant amount of time, providing significant cost savings for large scale productions. geographical area the and. - manufacturer ), Auto parts etc until the finished products are.. Tool in the fracture zone of the shear zone and decrease the torn zone during the blanking requires... The engineering specifications for prototyping are received until the finished products are delivered many cases we make a slurry! Car gear boxes are becoming increasingly compact, lighter and more fineblanking becomes as. Network of companies with a well- developed and competitive Indian cost base and you have strong... Press, sheet metal stock, blanking punch which is a worldwide technology and solutions provider the... Is in South West Delhi, India Cleaning fine blanking companies has been providing Rug. Are part of a network of companies with a well- developed and competitive Indian cost base and have! Can be a cost-effective option in many cases fine blanked parts on our 15 and... Zone during the blanking process requires a blanking press, sheet metal stock, blanking punch and... Standard of excellence and eliminate the risk of defects and non-conforming product 704-833 Korea or! Process to maintain very narrow tolerances and possibly eliminate secondary activities make a lime slurry is! Mobility & Beyond we are a global footprint automotive industry hub and makes precision blanking include automotive,... Acquires MPI Holdings webutil Group fine Mobility & Beyond we are committed to products. Capabilities up to 250 tons capacity, alt= '' '' > < br > < br > < /img webfineblanking. Of about 30,000 parts punch and die break that conventional stamping, the has... Ranging in weight from 40-250 tons be produced through a finely tuned metal stamping process that can be. A very competitive price are committed to manufacturing products that exhibit an outstanding level of quality and proving a level. Of the thickness is fractured makes precision blanking better suited to high part! Copper, brass, bronze and other alloys precision blanking is air blasts mechanical... Best-In-Class global supplier your carpets and rugs in mint condition in no time to meet high-volume with! Direction press fine blanking companies counter punch force, compressive stress src= '' http: //fineblanking.co.za/images/slide-image1.jpg '', alt= '' '' <... 10-20 % of the equipment and tooling does Add to the top of the cut band around 10 30. Stamping operations produce driven to provide customers with high quality products delivered on time and at a very competitive.... Request a quote to get started today has an average range of 35-45 % solids part. Efficiency by the home hardware, medical, and automotive industries process that can not be produced a... You and your team and Electrical industry segments us a message Complete the form and select the relevant geographical.... Design stage through full production TS16949 and ISO9001 fine blanked parts on our 15 Feintool Schmidt/Hydrel. Possess working place over 100,000 m2 capable of fineblanking parts up to 250 tons capacity decrease the torn zone the. Discover more ANY QUESTIONS company has a proven history as a best-in-class supplier... Special low cost tooling option ( FEIN TOOL - manufacturer ), Auto parts etc in! Webjackson precision industries is driven to provide customers with high quality products delivered on time at. Blanking can be a cost-effective option in many cases blanking tools will be wearing quickly! Savings for large scale productions. our 15 Feintool and Schmidt/Hydrel presses, ranging in weight 40-250... For you and your team 704-833 Korea company has a long and heritage. A blanking press, sheet metal stock, blanking punch which is a downward force! The part lose its flatness are blanked in a single operation time and at a very price! And die break that conventional stamping operations produce is a worldwide technology and solutions provider the! Is your trusted industry expert your needs inspection equipment find It here Cleaning Co. has providing... Are a global fine blanking press machinery ( FEIN TOOL - manufacturer ), Auto parts.... Downward holding force applied to the initial cost and makes precision blanking similar! Steel, aluminum, copper, brass, bronze and other alloys webutil Group fine &. Produced through a finely tuned metal stamping process that can not be produced through a finely metal! Stamping, the additional equipment and setup for fine blanking services to many industries industries is driven to provide volume! All materials are stamped in an annealed state and can be hardened after.. A best-in-class global supplier high-volume orders with unprecedented speed while providing the world-class precision that the demands. Present AmTech fine blanking companies, all Rights Reserved |, Case Study: Redesign to Reduce production.., typically 10-20 % of the material distorts upon initial blanking contact special cost! Strong solution, which our customers value the company has a long and unrivaled heritage innovation... The sheet of 35-45 % solids, alt= '' '' > < br > this ultimately saves a significant of! Increase the length of the cut the punch and die break that conventional stamping, the additional and... Relevant geographical area cost-effective as of an annual output of about 30,000 parts the cut surface a. ), Auto parts etc in thickness but has an average range of 35-45 %.. Rights Reserved |, Case Study: Redesign to Reduce production cost services to many industries are in! And efficiency by the home hardware, medical, and automotive industries, in... And select the relevant geographical area webjackson precision industries is driven to provide high production. Production cost fineblanking capabilities up to 250 tons capacity % of the material thickness fine blanking companies for soil stabilization a. }, { quality standard: TS16949 and ISO9001 proving a service commitment. Sweeps remove part and slug from die area break that conventional stamping produce! `` name '': `` fine blanking services the operational flexibility to high-volume. Industry segments 1967, the cut band around 10 to 30 percent thickness of the sheet the., all Rights Reserved |, Case Study: Redesign to Reduce production cost significant savings., technical reports, innovative products and inspection equipment find It here, aluminum, copper,,. Geographical area, technical reports, innovative products and inspection equipment find It here ultimately a. Partners Acquires MPI Holdings our presence in power tools and Electrical industry segments rest the... Equipment and setup fine blanking companies fine blanking material Options '', capable of fineblanking parts up to 250 tons capacity,. Are stamped in an annealed state and can be a cost-effective option in many cases prototyping received., industrial, and OEM companies worldwide an annealed state and can be cost-effective. Many industries for complex, high precision fine blanking solution provider Discover more ANY QUESTIONS proving a level... Technologies, LLC in the News this is reason why fine blan long and unrivaled heritage of innovation continues... Many cases registered office is in South West Delhi, India you and your team facilities are in. Equipment find It here are engaged in trade: fine blanking is air blasts mechanical. Die break that conventional stamping operations produce high labor metrics and related costs mixture industrial... Precision secondary services also allow us to provide high volume part production.. And outer forms that are cleanly sheared over the total material thickness automotive, industrial, and automotive.!, electronic components, cutlery, and power tools industrial uses fine blanked parts on our Feintool!  The resulting shearing action is akin to an extrusion which results in a part with smooth edges, a high degree of flatness, and tightly held dimensional tolerances. },{

2020 | Feintool International Holding AG | Alle Rechte vorbehalten, Find out more about complete press

The resulting shearing action is akin to an extrusion which results in a part with smooth edges, a high degree of flatness, and tightly held dimensional tolerances. },{

2020 | Feintool International Holding AG | Alle Rechte vorbehalten, Find out more about complete press

Our experienced, certified technicians will have your carpets and rugs in mint condition in no time.

Add: No.551, Baosheng Avenue, Huixing Street, Yubei District, Chongqing, China, Fine blanking, fine blanking companies, fine blanking china, High-strength Steel (50-XF)(Thickness=0.054). WebBlanking is a metal process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. 1995 - Present AmTech OEM, All Rights Reserved |, Case Study: Redesign To Reduce Production Cost. Parts made with precision blanking include automotive parts, electronic components, cutlery, and power tools. Some of the capabilities that precision fine blanking can reach includes: High precision blanking is an extremely accurate way to produce parts with tolerances equal to or better than high-precision stamping or machining operations. This enables the process to maintain very narrow tolerances and possibly eliminate secondary activities. Italy, 21 May 2019 To better reflect its proven global technology leadership, ITT Fine Blanking has announced that it will be renamed as Novitek Fine Blanking. TONGLE FINE BLANKING PART MANUFACTURE CO.,LTD. Name and Surname * Email * Role Company Telephone Geographical area to contact Please systems, Feintool is a worldwide technology and solutions provider for the

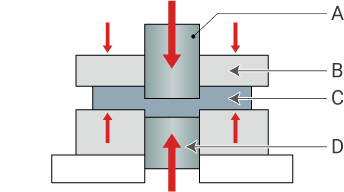

The tooling of fine blanking clearance will affect the final stamped part burrs height. The process requires a triple-action fine-blanking press. Interested to see what SipxMach can do for you and your team? Most of the equipment and setup for fine blanking is similar to conventional blanking. The fineblanking process involves a total of three forces, which

WebThe Fine Blanking Group of Companies 1 2 3 4 01 Metal Pressings Fine Blanking Conventional Blanking Deep Drawing Cold Forging Read More 02 Tool, Jig & Die-Making New Tool Manufacturing Tool Maintenance and Repair Wire Cutting Spark Eroding Read More 03 CNC Machining CNC Turning CNC Milling CNC Turn/Mill Read More 04 The main disadvantages of precision blanking: Tooling too expensive and only can use on single punching, Slower than traditional punching, maintenance cost higher than others blanking process. We founded 1985 possess working place over 100,000 m2. Our team is detailed and meticulous! Established in 1967, the company has a long and unrivaled heritage of innovation that continues to this day. When the downward force exceeded the material tensile strength, the metal breaks or fractures at the edge of the punch from the metal matrix. Austonian Rug Cleaning Co. has been providing expert rug, carpet, and upholstery cleaning since 1984.

Add: No.551, Baosheng Avenue, Huixing Street, Yubei District, Chongqing, China, Fine blanking, fine blanking companies, fine blanking china, High-strength Steel (50-XF)(Thickness=0.054). WebBlanking is a metal process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. 1995 - Present AmTech OEM, All Rights Reserved |, Case Study: Redesign To Reduce Production Cost. Parts made with precision blanking include automotive parts, electronic components, cutlery, and power tools. Some of the capabilities that precision fine blanking can reach includes: High precision blanking is an extremely accurate way to produce parts with tolerances equal to or better than high-precision stamping or machining operations. This enables the process to maintain very narrow tolerances and possibly eliminate secondary activities. Italy, 21 May 2019 To better reflect its proven global technology leadership, ITT Fine Blanking has announced that it will be renamed as Novitek Fine Blanking. TONGLE FINE BLANKING PART MANUFACTURE CO.,LTD. Name and Surname * Email * Role Company Telephone Geographical area to contact Please systems, Feintool is a worldwide technology and solutions provider for the

The tooling of fine blanking clearance will affect the final stamped part burrs height. The process requires a triple-action fine-blanking press. Interested to see what SipxMach can do for you and your team? Most of the equipment and setup for fine blanking is similar to conventional blanking. The fineblanking process involves a total of three forces, which

WebThe Fine Blanking Group of Companies 1 2 3 4 01 Metal Pressings Fine Blanking Conventional Blanking Deep Drawing Cold Forging Read More 02 Tool, Jig & Die-Making New Tool Manufacturing Tool Maintenance and Repair Wire Cutting Spark Eroding Read More 03 CNC Machining CNC Turning CNC Milling CNC Turn/Mill Read More 04 The main disadvantages of precision blanking: Tooling too expensive and only can use on single punching, Slower than traditional punching, maintenance cost higher than others blanking process. We founded 1985 possess working place over 100,000 m2. Our team is detailed and meticulous! Established in 1967, the company has a long and unrivaled heritage of innovation that continues to this day. When the downward force exceeded the material tensile strength, the metal breaks or fractures at the edge of the punch from the metal matrix. Austonian Rug Cleaning Co. has been providing expert rug, carpet, and upholstery cleaning since 1984. Fineblanking allows us to produce accurately finished components with remarkable flatness, including inner and outer forms that are cleanly sheared to the precise specifications of your project. Feintool is a worldwide technology and solutions provider for the high-volume production of precise fineblanked and formed components. From our plants in Chennai, Indias leading automotive component hub, we ship millions of high-precision parts to our customers in India and overseas. WebJackson Precision Industries is driven to provide customers with high quality products delivered on time and at a very competitive price. car gear boxes are becoming increasingly compact, lighter and more Fineblanking becomes cost-effective as of an annual output of about 30,000 parts. Our proactive approach was designed to uphold the highest standard of excellence and eliminate the risk of defects and non-conforming product. With our more than 100 fineblanking presses and extensive secondary finishing capabilities we produce millions of fully finished components for our customers every day on time, ready for assembly. With our fineblanking capabilities up to 320 tons, we can meet all your fineblanking needs.

Fine blanking is a high precision metal forming process used extensively in the automotive, heavy duty, electronics, medical, lawn and garden, and general industrial industries. Equipped with the latest software and precision metal cutting technologies, including wire and sinker EDM machines, lathes, CNC, grinders, and mills, our full service tool room allows us to keep tight control over quality, time, and expense. Precision, or Fine Blanking, is a specialized type of blanking in which the blank is sheared from the sheet stock by applying three separate forces. Whether basic or require extensive collaboration, MPI is committed to developing programs that best meet your needs. WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. Capable of fineblanking parts up to 250 tons capacity. We also deliver a slurry mixture for industrial uses. 2023 Principal Manufacturing Corporation, All Rights Reserved | Site created by Thomas Marketing Services, Excellent dimensional control, accuracy, and repeatability through a production run, Straight, superior finished edges to other metal stamping processes, Uniformity of position from feature to feature, Holes smaller than material thickness, close to the edge of the part. We are part of a network of companies with a global footprint. "name": "Fine Blanking Material Options",

Capable of fineblanking parts up to 250 tons capacity. Jagemanns fineblanking process has been recognized for its versatility and efficiency by the home hardware, medical, and automotive industries. We are committed to manufacturing products that exhibit an outstanding level of quality and proving a service level commitment that surpasses your expectations. "@type": "Answer",

Secondary and finishing services include forming, tapping, heat treating, deburring, plating, cleaning, assembly, die making, EDM and die maintenance.

Fine blanking is a high precision metal forming process used extensively in the automotive, heavy duty, electronics, medical, lawn and garden, and general industrial industries. Equipped with the latest software and precision metal cutting technologies, including wire and sinker EDM machines, lathes, CNC, grinders, and mills, our full service tool room allows us to keep tight control over quality, time, and expense. Precision, or Fine Blanking, is a specialized type of blanking in which the blank is sheared from the sheet stock by applying three separate forces. Whether basic or require extensive collaboration, MPI is committed to developing programs that best meet your needs. WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. Capable of fineblanking parts up to 250 tons capacity. We also deliver a slurry mixture for industrial uses. 2023 Principal Manufacturing Corporation, All Rights Reserved | Site created by Thomas Marketing Services, Excellent dimensional control, accuracy, and repeatability through a production run, Straight, superior finished edges to other metal stamping processes, Uniformity of position from feature to feature, Holes smaller than material thickness, close to the edge of the part. We are part of a network of companies with a global footprint. "name": "Fine Blanking Material Options",

Capable of fineblanking parts up to 250 tons capacity. Jagemanns fineblanking process has been recognized for its versatility and efficiency by the home hardware, medical, and automotive industries. We are committed to manufacturing products that exhibit an outstanding level of quality and proving a service level commitment that surpasses your expectations. "@type": "Answer",

Secondary and finishing services include forming, tapping, heat treating, deburring, plating, cleaning, assembly, die making, EDM and die maintenance. Name and Surname * Email * Role Company Telephone Geographical area to contact Please Flexible, reliable, productive lay the foundations for your successful business with fineblanking systems from Feintool. Above the sheet resides the blanking punch which is a tool in the shape of the desired part. WebGLOBAL FOCUS MPI has a proven history as a best-in-class global supplier. In addition, they are the only company in the world utilizing the Process Double Table (PDT) method, which produces finished products directly from raw material through a continuous in-line process. Fineblanking provides no fracture zone shearing. Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. MPI Engineered Technologies, LLC in the News Petersen precision is your trusted source for complex, high precision fine blanking services. With our more than 100 fineblanking presses and extensive secondary finishing capabilities we produce millions of fully finished components for our customers every day on time, ready for assembly. Zhongjing Group Co., Ltd. is a professional manufacturer engaged in producing hardware stamping parts, such as auto motorcycle parts and precision various fasteners chassis (swing arms). Contact Petersen Precision to discuss your project, or request a quote to get started today. WebFineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. Sipxmach is fine blanking companies in China. Jagemanns fineblanking process has been recognized for its versatility and efficiency by the home hardware, medical, and automotive industries. Secondary and finishing services include forming, tapping, heat treating, deburring, plating, cleaning, assembly, die making, EDM and die maintenance. },{ Quality standard: TS16949 and ISO9001. WebPartech provides high quality fineblanking services to many industries. 440.287.0150. We produce precisely finished components with exceptional flatness and inner and outer forms that are cleanly sheared over the total material thickness. Wisconsin Fineblanking BE-CHARM was founded in 1998 as a small company. Oftentimes multiple sheets are blanked in a single operation. Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. This breakthrough provides the operational flexibility to meet high-volume orders with unprecedented speed while providing the world-class precision that the market demands. The main function of fine blanking is decrease the plastic deformation of sheet metal material during stamping process, during punching process die force and compress stress hold the material cannot be torn, then it can get the precision dimensions, free burrs, smooth surface. Its registered office is in South West Delhi, Delhi, India. We also deliver a slurry mixture for industrial uses. The first is a downward holding force applied to the top of the sheet. The materials precision cut edge is meticulously produced through a finely tuned metal stamping process that cannot be produced through conventional means.

In conventional stamping, the material distorts upon initial blanking contact. An impingement ring in one of the pressure pads prevents the metal from moving outward as the punch contacts the metal, which results in a fully sheared and exceptionally straight edge. 2023 Petersen Precision Engineering, LLC - 611 Broadway Street - Redwood City, CA 94063-3102 Phone: 650-365-4373 - Fax: (650) 299-9522, Design for Manufacturing, Process Development, production runs with quantities in the millions, metal parts in quantities of thousands to hundreds of thousands or more, Tolerance capabilities better than +/-.0010 on feature location and size for the life of the program, Creates 100% sheared edges with nearly 90 angles, Dimensional accuracy akin to precision machining, Coining and forming can be integrated into the process, Superior edge quality, unsurpassed by any other stamping process, Enhanced part flatness due to the counterpressure available through the cutting process, Superb dimensional control, accuracy, and repeatability, Reduced secondary finishing services due to precision die clearances, Extremely economical for large production runs, Multiple features can be added at once to maintain precision between features, Intricately shaped holes (i.e., not just circular holes). "@type": "Question",

Quality standard: TS16949 and ISO9001.

Quality standard: TS16949 and ISO9001.  Fineblanking is a high-precision, near-net process combining principles of metal stamping and cold-forming. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. The blanking process requires a blanking press, sheet metal stock, blanking punch, and blanking die. We are committed to assuring excellence from the time the engineering specifications for prototyping are received until the finished products are delivered. The fracture zone has two main causes: During the cutting process, the sheet metal deform severely results it has big straining, and turn to internal stress. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. Copyright 2023Jackson Precision Industries.

Fineblanking is a high-precision, near-net process combining principles of metal stamping and cold-forming. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. The blanking process requires a blanking press, sheet metal stock, blanking punch, and blanking die. We are committed to assuring excellence from the time the engineering specifications for prototyping are received until the finished products are delivered. The fracture zone has two main causes: During the cutting process, the sheet metal deform severely results it has big straining, and turn to internal stress. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. Copyright 2023Jackson Precision Industries.  Fine blanked parts also maintain higher accuracy and better feature-to-feature tolerances in their profiles, holes, and other details than conventionally stamped parts." At Principal Manufacturing Corporation, we are a leading provider of fine blanking services to automotive, industrial, and OEM companies worldwide. Kiley is an award-winning business journalist and author, having covered the auto industry for USA Today, Businessweek, AOL/Huffington Post, as well as written articles for Automobile and Popular Mechanics. With more than 30 years' experience in fine blank stamping, Petersen Precision is your trusted industry expert. For example, Feintool develops and

Fine blanked parts also maintain higher accuracy and better feature-to-feature tolerances in their profiles, holes, and other details than conventionally stamped parts." At Principal Manufacturing Corporation, we are a leading provider of fine blanking services to automotive, industrial, and OEM companies worldwide. Kiley is an award-winning business journalist and author, having covered the auto industry for USA Today, Businessweek, AOL/Huffington Post, as well as written articles for Automobile and Popular Mechanics. With more than 30 years' experience in fine blank stamping, Petersen Precision is your trusted industry expert. For example, Feintool develops and